OOF2: The Manual

Name

Anneal (Anneal) — Move nodes randomly and accept the ones that meet the acceptance criterion.

Synopsis

Anneal(targets,criterion,T,delta,iteration)

Details

-

Base class:

SkeletonModifier -

Parameters:

targets- Which nodes to move. Type: An object of the

FiddleNodesTargetsclass. criterion- Acceptance criterion Type: An object of the

SkelModCriterionclass. T- Failed moves will be accepted if T>0 and exp(-diffE/T) > r, where diffE is the energy gained and r is a random number between 0 and 1. Type: A real number.

delta- Width of the distribution of attempted node motions, in units of the pixel size. Type: A real number.

iteration- Iteration method. Type: An object of the

IterationManagerclass.

Description

Anneal is a Skeleton modifier that

moves Nodes to random positions, accepting or rejecting moves

according to the given criterion. It is

similar to a simulated annealing simulation in statistical

mechanics, from which it gets its name. Instead of minimizing the

free energy of a system of particles, it minimizes the effective energy

of a Skeleton.

The general procedure for a single iteration of

Anneal is as follows:

-

Collect target nodes according to the given

targetsparameter. The collectedNodesare re-ordered randomly to remove any potential artifacts from the original ordering ofNodes. This re-ordering is repeated at every iteration. -

Give each

Nodea single chance to move to a randomly assigned new position. OOF2 computes the new position from and

and

are random numbers chosen from a Gaussian distribution of

width

are random numbers chosen from a Gaussian distribution of

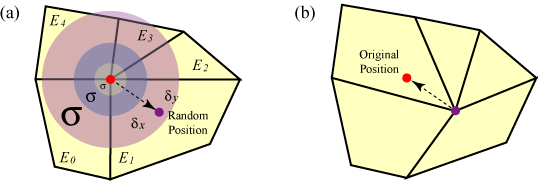

width deltaand mean 0.0.deltais in units of theMicrostructurepixel size.Figure 6.59(a) shows a node (the big red dot) that is about to move to a new position. Before making the move, OOF2 computes the total effective energy of all of the neighboring elements of the node.

-

After moving each

Node, the given acceptancecriteriondecides whether or not the move is acceptable. -

If the move is unacceptable according to the acceptance

criterion, OOF2 may still accept the move if the annealing is being done at a non-zero temperature. The parameterTsets the effective temperature of the annealing process. Unacceptable moves are accepted with a probabilitywhere

is the difference between the

effective energies of the new and old

is the difference between the

effective energies of the new and old Elementconfigurations.

Figure 6.59. Annealing

(a) A node moves by

and

and

.

The node move affects

four neighboring elements, E0,

E1, E2, and

E3. (b) The node has moved to a

new position. If the move doesn't satisfy the given acceptance

.

The node move affects

four neighboring elements, E0,

E1, E2, and

E3. (b) The node has moved to a

new position. If the move doesn't satisfy the given acceptance

criterion (computed based on its four

affected elements), it'll be rejected and the node will

move back to its original position.

Successful annealing usually requires a number of iterations. On

each iteration, OOF2 makes one attempt to move each node. The

number of iterations is controlled by the

iteration parameter, which can be set to

perform a fixed number of iterations or to stop after some

condition is satisfied. See IterationManager for the details.

Statistics for each step of the annealing process are printed in the OOF2 Message window. For example,

Iteration 1: E = 1.1916e+01, deltaE=-1.2495e-01 ( 1.049%), Acceptance Rate = 19.1%

Iteration 2: E = 1.1391e+01, deltaE=-1.7564e-01 ( 1.542%), Acceptance Rate = 25.5%

Iteration 3: E = 1.0638e+01, deltaE=-1.1883e-01 ( 1.117%), Acceptance Rate = 22.3%

Iteration 4: E = 1.0095e+01, deltaE=-1.4345e-01 ( 1.421%), Acceptance Rate = 21.0%

Iteration 5: E = 9.5440e+00, deltaE=-8.3725e-02 ( 0.877%), Acceptance Rate = 21.0%

The listing shows the iteration number, the total energy

(E) of the Skeleton, the absolute

change in energy (deltaE) during

the iteration, the percentage change in energy, and the move acceptance rate.

If the change in energy or the acceptance rate gets too small, the

annealing process is not being effective at improving the Skeleton.

Using ConditionalIteration as

the iteration parameter can stop the process

when it becomes ineffective.

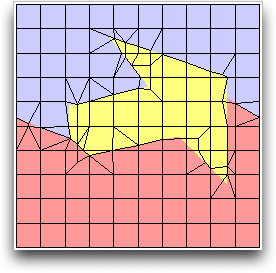

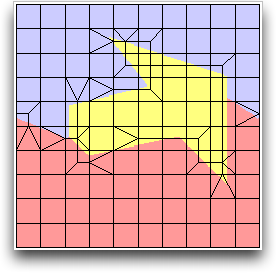

Figure 6.60 shows a Skeleton that has been

refined once. Figure 6.61 shows the same skeleton after snapping nodes to the

material boundaries. Snapping was done with a large α (0.9)

so there are some badly misshapen elements. Notice that the

border of the arrow shape does not coincide well with the element

edges in many spots. Further iterations of SnapNodes does not improve matters.

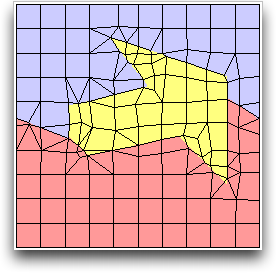

However, the Skeleton can be improved by Annealing. Annealing with

targets=AllNodes,

criterion=AverageEnergy(alpha=0.9),

and delta=1.0 for 20 iterations produced the

Skeleton shown in Figure 6.62. The Skeleton

edges match the boundary of the arrow shape much more

exactly. Further annealing would improve it even more, although

SplitQuads and Rationalize should probably be used

first.

Figure 6.60. A Slightly Refined Skeleton

A Skeleton for a Microstructure containing three materials. The

material boundaries do not align well with the Element edges.

Figure 6.62. An Annealed Skeleton

The Skeleton from Figure 6.61 after being

annealed. The resolution of the sharp corners has been much

improved.

![[Tip]](IMAGES/tip.png) |

Tip |

|---|---|

|

Even though the example shown above concentrates on resolving

tricky material boundaries (meaning it puts more emphasis on

homogeneity

than shape), |

![[Tip]](IMAGES/tip.png) |

Tip |

|---|---|

|

A good way to anneal efficiently is to apply it only to |

![\[P = \exp{(-E_\mathrm{diff}/T)}\]](equations/6.5.2-eq-2.gif)