Home

Simulation Example

Article (280kB

PDF)

Downloads

Working Group

Bill

Boettinger

Ursula

Kattner

Kil-Won Moon

|

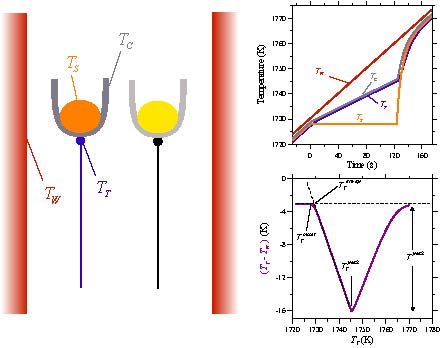

Differential thermal analysis (DTA) measurements are a standard method

of determining standard method of determining transformation temperatures

of materials. Accurate interpretation of these measurements is essential

when they are used to infer the location of equilibrium phase diagram boundaries.

The accuracy of the measurements is affected by the details of heat transfer

within the measurement cell and by transformation kinetics. Simulations

can provide understanding into how thermal events from transformations are

reflected in the DTA signal and can enable more accurate interpretation of

DTA results from samples with unknown characteristics. A heat flow model

of a DTA and thermal characteristics obtained by fitting experimental results

for a pure metal, the response of the DTA is modeled for the melting

and solidification of alloys.

As input to the calculation we use enthalpy vs. temperature values

obtained for full equilibrium (lever law)

and for Scheil freezing assumptions.

It should be noted that these are extreme cases. DTA melting simulations,

using the lever enthalpy-temperature relation, would apply to an alloy

equilibrated prior to melting and where diffusion was adequate to guarantee

spatial concentration uniformity of all phases during melting. DTA melting

simulations, using the Scheil enthalpy calculations, would apply to a microstructure

that was solidified and remelted with no solid diffusion. The melting of

an equilibrated alloy as well as an as-cast sample requires an analysis

of solid diffusion for both the freezing process and the melting process.

|